Along those lines, could you please talk a bit about the most popular (as well as the least popular) materials used for printing 3D fins, their upsides and downsides, and what you would like to experiment with next?

PLA is definitely the most popular 3D print material for desktop 3D printers – it is cheap and it is easy to print, and the fumes emitted during printing are quite low. However, one of its weaknesses is that it’s a brittle material, meaning that it can snap quite easily, which is not great for surf fins. A lot of my early fins were 3D printed in another very popular plastic, ABS. This is much more durable and one of the most common plastics found in many of your electronic products, but more difficult to print as it can warp during the transition from hot to cold experienced during printing. More recently I’ve experimented with carbon fibre infused nylon, which is strong and lightweight, but the material requires careful storage as it likes to absorb moisture from the air, and I’ve been printing it on quite an expensive 3D printer that most people wouldn’t own at home.

I think next I’d be interested in experimenting with some recycled filaments. For example, there are some filaments you can buy that have been made from recycled fishing nets, recycled PET bottles and others. Just as 3D printing allows you to experiment with the design, it also allows you to experiment with different materials.

In the paper, you wrote that “the shape of surfboard fins have largely been bio-inspired, assimilating proportions from the dorsal fins of fish and mammals such as the dolphin.” I’m curious to know if you have experimented – or know of someone who has – with other bio-inspired shapes besides the aforementioned? And if not, do you see potential somewhere?

For surf fins, no I’m not aware of any other shapes people are experimenting with that are completely different to the typical fin shapes. The engineering side of me says that these shapes have been optimised using advanced computer simulation software to achieve specific properties in the water, and it is unlikely that a completely new shape will perform better. Evolution has also seen these shapes tested over millions of years! The more creative design side of me wonders whether it still wouldn’t be fun to try some different shapes – perhaps inspired by aircraft like the stealth fighter? Or with textured surfaces, rather than being completely smooth? There is certainly potential to use 3D printing to try different things that manufacturers are unlikely to try.

During this research, you observed closely all aspects of fin design. Was there a particular element – such as fin placement or foil, for instance – that struck you as being generally underestimated or overlooked?

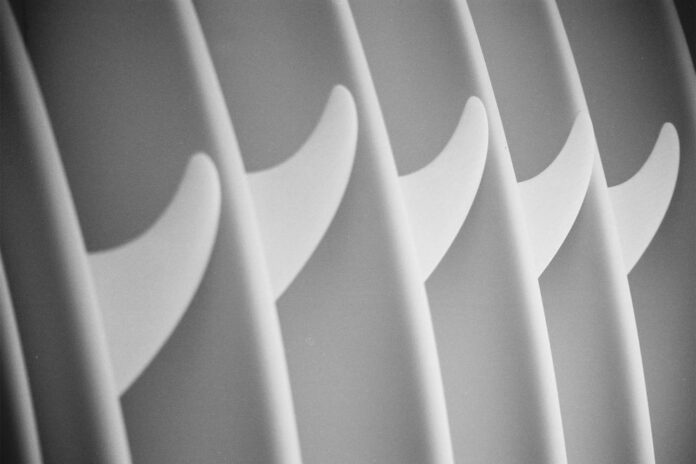

The thing that I realised was how complex such a seemingly simple part was! I initially started this project thinking I’d just need a few simple variables to allow people to create just about any fin shape they wanted, but as I dove into the research, I realised there were many different parts of the fin shape that provide different performance characteristics. I ended up with quite a few different parameters that people can change and interact with in my CAD system, shown below. I probably haven’t surfed long enough or with enough different fins to really understand the practical effects each of these play on performance, but I think many people will be surprised about what sorts of dimensions could be changed and that they may like to experiment with.